Raw materials shortage: What can you as a manufacturer do?

Customers that have to wait for months on their orders, empty shelves in stores and unseen increases in price: the manufacturing industry is currently struggling with a worldwide shortage of raw materials. The lack of materials such as lumber, aluminum or plastic has caused a crisis for manufacturers. But where does this sudden scarcity come from? And what is the best way for companies to handle this situation?

Origin of the raw materials shortage

The main cause for the current worldwide shortages is the COVID-19 pandemic. China, the factory of the world, was the first to deal with the virus that completely shut down the manufacturing industry for months. The first signs of scarcity were therefore already visible before COVID-19 spread to the rest of the world. Later the demand for goods only kept growing because consumers could no longer spend their money on services or experiences such as tourism during the lockdowns. The market that was destabilized by the coronavirus, has up to this day not yet recovered.

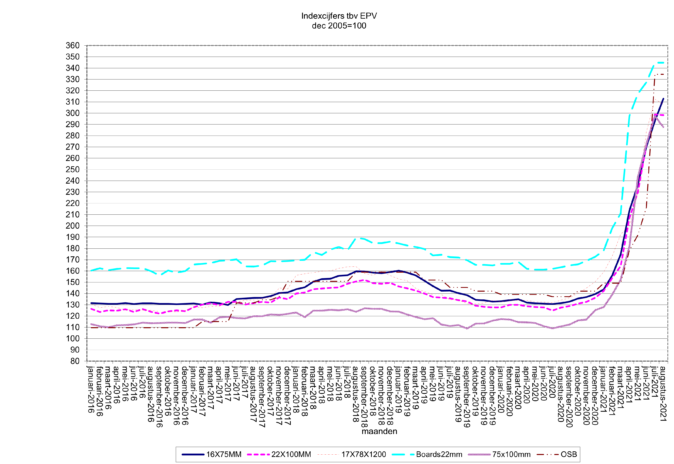

Index of lumber prices since January 2016 until August 2021 (EPV, 2021)

Challenges

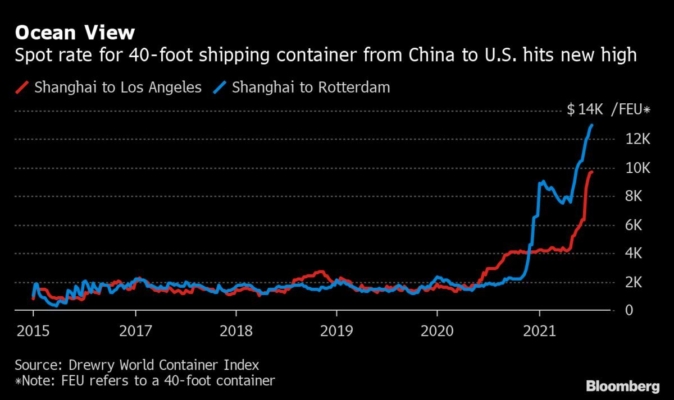

This situation brings some challenges for manufacturing companies. Suppliers are raising their prices, leaving manufacturers no choice but to increase their prices for end customers as well. Transport has also gotten more expensive, while the waiting times continue to get longer. To deal with this crisis, a lot of manufacturers started panic buying huge amounts of stock, which only worsened the problems. How can you as a manufacturer handle the shortages in a smarter way? We’re bundling some tips.

- First thing to consider is whether you handle your scarce stock efficiently and optimally. Here we highly recommend choosing for a predictive strategy based on market research. This will help you to understand what resources will be needed at what time. This data, together with the inventory information, needs regular updates to prepare your business for shortages or unusually high sales volumes. Keep in mind that internal coordination between different departments is crucial when applying a predictive strategy throughout your business.

- A second strategy would be to decrease the amount of waste in production. You can do this by applying the principles of lean manufacturing or by minimizing the number of mistakes during the production process. Lots of mistakes emerge from invalid orders made before production: wrong entries in the ERP system, incorrect configurations that cannot be validated or processed orders that are not aligned with the customer’s wishes create waste. To handle your stock more carefully, automated validation and order entry can be a smart solution.

- Another way you can deal with the shortages of raw materials is avoiding delays as much as possible. End customers are already waiting a lot longer on their orders (the waiting times in the lumber sector have doubled for example), so it can be beneficial to optimize transport, semi-finished products, and end products through the production process. This will save you time, keep your customers happy, and decrease the risk of damage.

Index of the container prices from 2015 until 2021 (Bloomberg, 2021)

- Lastly, it is also crucial to take the human aspect into account. By building and maintaining relationships of trust with customers, distributors, and suppliers, you will get a better understanding of how the market works and you might even gain insights in the stock levels of companies. These types of relationships are a powerful foundation for high-quality collaborations between companies and can therefore be an interesting strategy in times of worldwide shortages.

Since the economy keeps on growing worldwide, it doesn’t look like the shortages of raw materials for the manufacturing industry will be solved soon. Manufacturers should therefore start looking into smart solutions. Our tips are just the beginning.

Interested in CPQ?

Follow us

Stay informed

Subscribe to our newsletter

Related articles

5G: A new challenge for manufacturers

The current situation of the manufacturing industry is very complex, as companies evolve in a very competitive environment. But competition is not the only challenge manufacturers face, as product life cycles have been growing shorter and customers are demanding customized products more and more. The arrival of 5G will ease these challenges, but it is important to be prepared, by investing in the right software today.

The war for talent: How to protect your company from the talent gap and the great resignation?

The war for talent rages on. Since the COVID-19 pandemic, companies are not only dealing with a talent gap, or a lack of skills in the workforce, but also with the great resignation, making people rethink their salaries, working conditions, and job satisfaction. The number of people quitting their jobs has rarely been higher. Studies have shown that the manufacturing industry in particular has been hit hard by this job market crisis. How can you protect your company from the increasing influence of the talent gap and the great resignation?

How to increase sales for your manufacturing business

Manufacturers are often struggling with long and complex sales processes, making it hard to increase sales. This has to do with the complex nature of the goods, but also with the fact that B2B sales requires various stakeholders to work together. On top of that, the manufacturing market has had some intrusive changes: increasingly demanding B2B buyers and global competition continue to impact companies. Increasing sales in manufacturing is therefore not as straightforward as it often is in other industries. We are bundling some tips to increase your sales again. Read along!