- Home

- Industries

- Vehicles

How CPQ software helps industrial vehicle manufacturers

Industrial vehicle manufacturing comes with unique challenges: complex configurations, demanding compliance standards, and high expectations from resellers and end customers. CPQ software brings clarity to the process, helping you generate quotes faster and reduce costly errors.

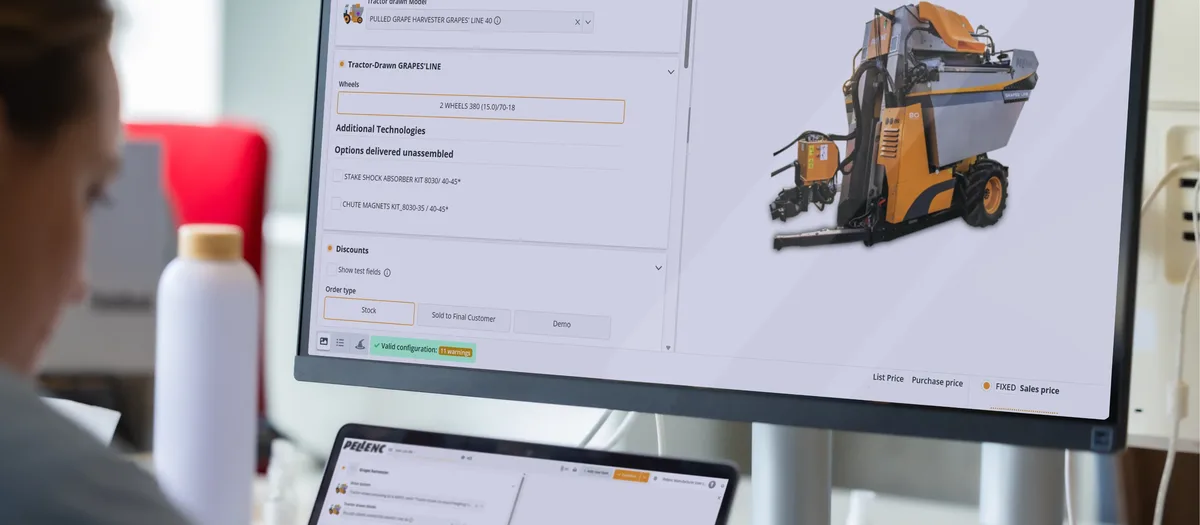

Error-free configuration, integrated with your systems

In industrial vehicle manufacturing, accuracy is everything. From axle layouts to hydraulic systems and emission controls, a single mistake can cause costly delays. Configure Price Quote software, like Hive CPQ, ensures every configuration is correct, compliant, and production-ready.

- 100% up-to-date options and pricing: seamlessly synced with your ERP and PIM systems.

- Error-free and automated Bill of Materials, to streamline production and minimize expensive errors.

- Built-in engineering rules and compliance standards, including ISO and EU Stage V, so only technically valid options can be selected.

Accurate quotes in minutes, not days

In industrial vehicle sales, speed matters. Lengthy quote cycles can cost you deals, while fast, accurate proposals give you a real competitive edge. Hive CPQ helps your sales teams spend less time on paperwork and more time with customers.

- Automated pricing calculations: including regional tariffs, reseller discounts, and material costs

- Easy document generation: create all essential sales documents like quotes and order summaries, as well as technical sheets and operation manuals for use after the sale.

- Less back-and-forth communication: no more endless mail threads, but accurate timelines and clear pricing from the start to keep projects moving without delays

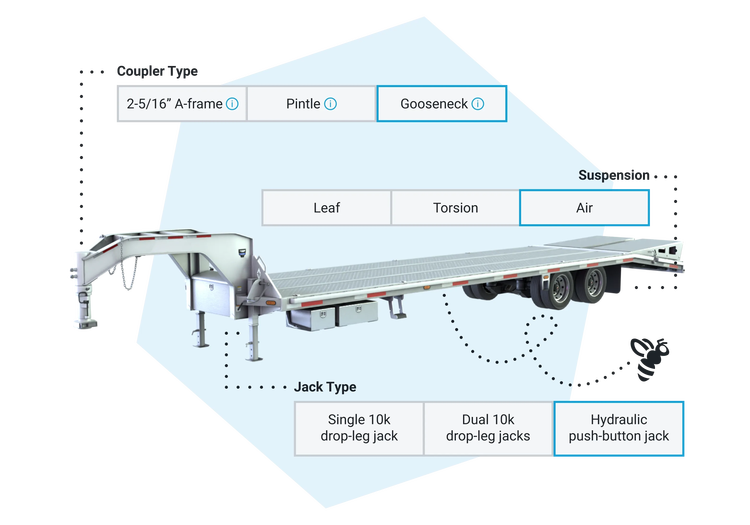

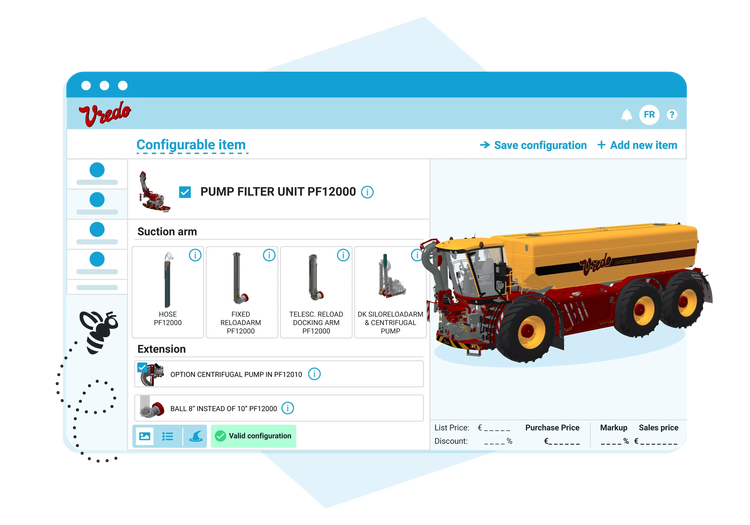

Replace bulky catalogs with 3D visuals

Static catalogs can’t show how complex vehicle components fit and work together. Hive CPQ brings your products to life with clear 3D models that give resellers and customers the clarity they need.

- From static to interactive: replace paper catalogs and PDFs with dynamic 3D models that show every detail clearly.

- Clear and focused visuals: show only the relevant options for each vehicle model.

- Self-service experience: the CPQ guides customers through configurations without relying on back-office support.

Seamless spare parts ordering

Aftermarket parts are a key element of customer support, but manual ordering often causes delays and errors. With a spare parts store fully integrated into your configurator, resellers can quickly and confidently order the right components, with guaranteed compatibility, even for legacy models.

- Easy search: let end-customers or resellers find the correct parts by serial number or exploded view.

- Fewer errors: reduce support questions and incorrect orders with clear, validated selections.

- Always in sync: stock data automatically updates from your ERP system, so availability is never in doubt.

Support your reseller network with ease

Hive CPQ’s dealer platform standardizes workflows so your resellers can sell with confidence, always using the right pricing, compliance rules, and branding. With real-time CRM integrations, you can gain insights into reseller performance and customer demand.

- Validated configurations for resellers, with rule-based logic ensuring only valid combinations of chassis, options, and accessories.

- Flexible setup: lock or predefine base models while allowing final customizations up until the production cut-off point.

- Margin protection: control end-customer pricing and safeguard your profitability across all sales channels.

Grow your vehicle manufacturing business with confidence

Book a demo to see how Hive CPQ can transform your sales process. Automate with peace of mind, scale faster, and stay fully compliant – every step of the way.

How CPQ solves today’s vehicle manufacturing challenges

Still relying on engineer-to-order for your vehicles? With Hive CPQ, you can move to a configure-to-order approach that saves time, strengthens dealer and customer relationships, and boosts your revenue. It’s the easiest way to overcome the most common challenges in vehicle manufacturing.