Raw materials shortage: What can you as a manufacturer do?

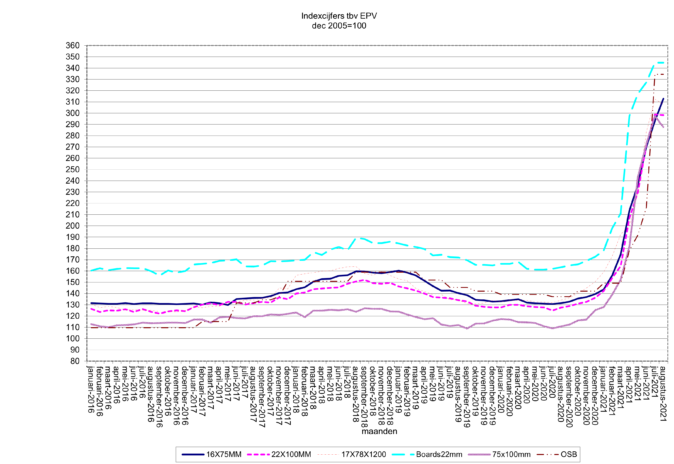

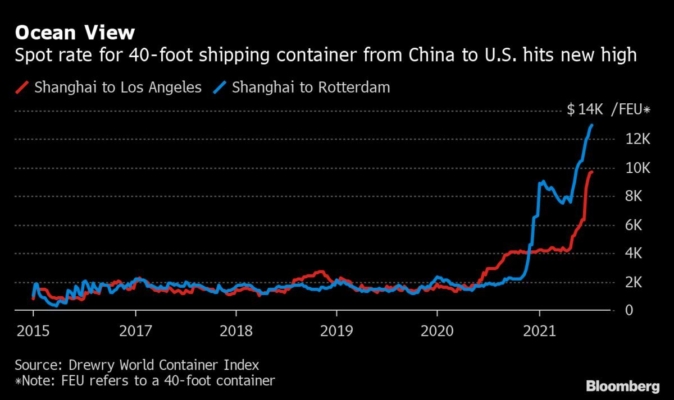

Customers that have to wait for months on their orders, empty shelves in stores and unseen increases in price: the manufacturing industry is currently struggling with a worldwide shortage of raw materials. The lack of materials such as lumber, aluminum or plastic has caused a crisis for manufacturers. But where does this sudden scarcity come from? And what is the best way for companies to handle this situation?

October 15, 2021

Written by

Vera Vingerhoets