- Home

- Customer cases

- Haco boosts dealer autonomy and standardizes sales with Hive CPQ

Haco boosts dealer autonomy and standardizes sales with Hive CPQ

Haco, a global industrial machinery manufacturer, partnered with Hive CPQ to modernize its sales configuration process. In 2022, the company replaced a custom-built CPQ tool with Hive’s cloud platform integrated into Microsoft Dynamics 365 Business Central. We spoke with IT Manager Sam Hast to discuss how the new quoting solution has empowered Haco’s dealers worldwide.

Introduction

About Haco

Haco is an internationally known manufacturer of industrial machine tools, founded in 1965. The company produces pressbrakes, shearing machines, lathes and advanced CNC equipment to customers around the world.

Headquartered in Ardooie, Belgium, Haco employs over 400 people and serves customers through an extensive network of distributors worldwide. Haco’s heritage of innovation and customer-centric design has made it a trusted name in machinery manufacturing for decades.

Problem

The challenge: From customization to standardization

IT Manager Sam Hast explains: “Our products are highly complex. The pressbrakes and shearing machines for metalworking in particular have a big number of options. This allows us to offer customers a machine that entirely meets their needs.”

However, the product complexity also had an impact on Haco’s operations. “One of our employees wrote his own ERP and CPQ system. The CPQ part, called ‘Haco Offer’, worked quite well. But when the developer retired, we realized that all knowledge was concentrated in one person.”

“Maintaining the system without him seemed like an impossible task. Especially since we wanted to add new products to Haco Offer, but no one in-house knew how to. So we started looking for a more standard ERP and CPQ solution.”

This idea was consistent with the broader strategic shift the company was undergoing at the time: away from customization, and toward greater standardization. “Not only in our products, but also in our processes,” Sam explains. The company embarked on a renewal process in 2022: Microsoft Dynamics 365 Business Central was picked as the new ERP system, and the search for an integrated CPQ solution began.

Haco Offer worked quite well, but when the developer retired, maintaining the system without his help seemed like an impossible task.

Solution

Self-service CPQ and seamless integration with ERP

“We had two important requirements for a CPQ system. On the one hand, it had to be easy to connect it with Business Central, and on the other hand, it was important that we could use and maintain it ourselves. At Haco, we believe in a hands-on approach, so we didn’t want a black box that only consultants could access,” Sam adds.

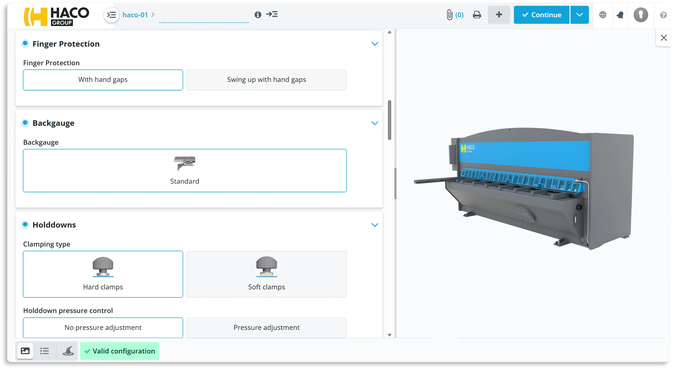

That’s when Haco learnt about Hive CPQ. The solution allows the company to build and maintain configurators in a user-friendly way. “Today, we no longer need the Hive team to add machines or product lines to the CPQ. With other CPQ vendors, this was often simply not an option.”

Haco has been using Hive CPQ for several years now to simplify the sales process. “Haco Offer has since been discontinued, so most of our dealers and sales reps are now active on Hive. They are in particular praising the user-friendliness of the platform. They used to have to work with an outdated interface – Hive feels much more modern to them.”

Our dealers can now independently create their own configurations, price calculations, and orders. With the push of a button, orders are sent to our ERP, including their Bill Of Materials. This saves us a lot of administrative work.

Dealers can now independently create their own configurations, price calculations, and orders. “Our dealers are spread all over the world: from Poland to Greece and Thailand. Luckily, Hive supports multiple languages and currencies.”

The internal Haco team is satisfied with the new order workflow: “With the push of a button, orders are sent to our ERP. The Bill of Materials is also automatically generated in Hive and immediately sent to the production team in Slovakia. This saves us a lot of administrative work.”

“Thanks to the integration between Hive CPQ and Microsoft Dynamics 365 Business Central, our intercompany flows are fully supported,” Sam concludes.

Process

Phased rollout and collaborative implantation

Haco opted for a phased rollout of their new CPQ solution. In an initial phase, Hive CPQ was set up as a standalone CPQ solution, so that it could replace Haco Offer in the short term. The Hive team built the first configurator for the most complex machine, and then passed on their knowledge to Haco through various workshops and the Hive Academy.

Sam then continued the work himself. “We recently launched a new model, a kind of entry-level model of our pressbrake, for example. I was able to add all the product logic into Hive CPQ myself. It allowed dealers to instantly offer it to their customers. It’s so simple!”

Recently, I added all product logic for a new product model, an entrymodel of our pressbrake, into Hive CPQ all by myself. So dealers can instantly offer it to their customers. It’s so simple!

However, the IT manager did encounter some resistance from time to time. “Haco Offer was completely customized, so everything our sales team asked for could be implemented. Now it’s different. Hive CPQ is more of a standard solution, which fit our strategy of moving from Engineer-To-Order to Configure-To-Order.”

“For example, we removed options that are only sold once every three years. That was met with some resistance from the sales team.” The Haco quotes would also undergo a transformation. Sam explains: “The quotes from Haco Offer were almost like a book, because each option was given a full description. We sat down together to make the quotes more concise. All of these adjustments were a big change for our employees.”

Now, the company mainly sees the advantages: administration has been simplified, internal sales teams create quotes faster, and the production process is immediately initiated and managed through a seamless integration with ERP. Thanks to Hive CPQ, it’s easier to get dealers excited about distributing new machines.

Future

Scaling CPQ across products and channels

What does the future hold for Haco? “We are currently working on building configurators for the lathes and fiber laser machines. These are more complex than our pressbrakes. But the great thing is: we handle the entire setup on our own, without help from the Hive team.”

Once all product lines are in Hive CPQ, the manufacturer wants to install an experience configurator on their website. This will allow visitors to create a configuration and request a quote for that specific product composition – without seeing prices.

With Hive CPQ, Haco has taken control of its sales processes. “The workflows are now running smoothly, dealers are more independent, and we can launch new models faster than ever. In short, I think we are ready for the future.”

Curious about what Hive CPQ can do for your business?

Key benefits of Hive CPQ for Haco

Dealer autonomy

Hive CPQ allows Haco's dealers to configure and quote, increasing independence and speed.

Seamlessly integrated

Orders flow directly to Business Central, eliminating manual order re-entry and errors.

Rapid product launches

Haco's team adds new products to the CPQ quickly, making them instantly available for dealers.

Standardized quoting

Hive CPQ ensures validated configurations and pricing across all regions.