- Home

- Customer cases

- S2 digitalizes door threshold sales with Hive CPQ

S2 digitalizes door threshold sales with Hive CPQ

S2, a Dutch company that is part of the Nauta Group, develops and supplies high-quality door and window hardware. Recently, they took a major digital step by streamlining the sales process of one of their product lines with Hive CPQ. We spoke with Patrick Kleinhuis, Account Manager at S2 for over eleven years, who helped build their new door threshold configurator – a tool that allows customers to design fully customized thresholds quickly and accurately, down to the very last millimeter.

Introduction

About S2

S2 is a trusted partner for the woodworking industry. The company designs, manufactures, and markets premium door and window hardware, including locks, hinges, cylinders, handles, and thresholds. Active in both the Netherlands and Belgium, S2 supplies the professional construction market as well as door and window manufacturers such as joineries and façade builders.

Challenge

Precision needed for new product

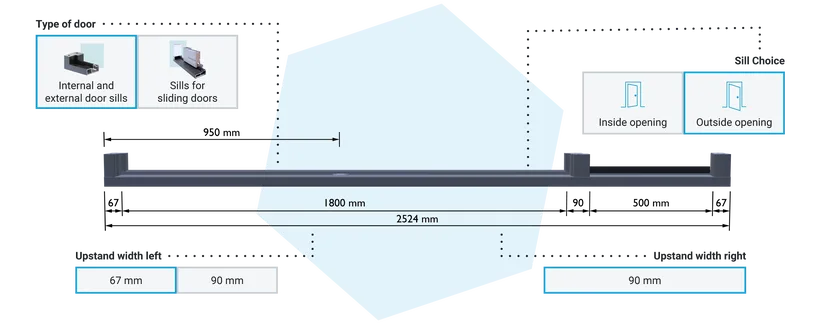

In 2024, S2 introduced their door thresholds as a new product line. They are used in both front and back doors as well as garden and garage doors, serving as a key element in the overall sealing and security of a building.

To support the sales process of the new product, the Deventer-based company partnered with Hive CPQ to create a custom threshold configurator. Thanks to the configurator, customers can now easily design and order tailored thresholds – accurate down to the millimeter, as precision is crucial for this type of product.

In search of a more efficient digital sales channel

Patrick: “When we first launched our threshold product line, the entire process – from configuration and price calculation to invoicing – was completely manual. Orders came in through a digital form, after which our sales team created a sales order and then a purchase order. Every bit of data had to be transferred by hand.

In the early phase, the order volume was still manageable, but we quickly realized that this manual process wouldn’t scale once sales started to grow. On top of that, the professional hardware trade has gone through major digital transformation in recent years – so we needed to make this product group digitally available as well.”

We quickly realized that our manual sales process wouldn’t work once order volumes for our new product started to grow.

“The previous process also left too much room for errors since we had to retype all the data manually. For a product that easily costs over a hundred euros, that’s not a risk you want to take. Often, mistakes were only discovered during installation, when it’s too late to fix them. We also wanted a connection to our ERP system and the CNC software that drives our production environment.”

Solution

“Decided on Hive CPQ right away”

“Our sister company Nauta BV was already developing a custom configurator with Hive CPQ,” Patrick explains. “They were very satisfied with their cylinder configurator, so the choice for Hive CPQ was an easy one. It matched perfectly with what we had in mind, so we didn’t even look for other solutions.”

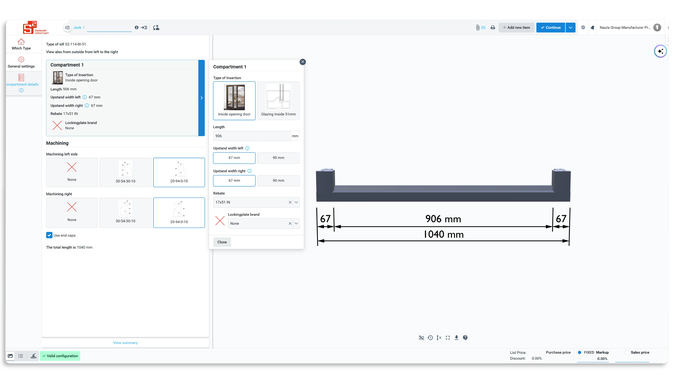

Integration with ERP and customers’ software

“One of the key factors for us was the integration with our ERP system, Wholesale. We also wanted a configuration process that’s clear and easy to use. It’s great that customers can instantly see what their final product will look like. And thanks to the automation Hive CPQ brings, our process is now much more future-proof.”

Patrick adds: “Our thresholds are mainly used in wooden door frames, and joinery factories are becoming more and more digital. They design their frames in software that automatically calculates how much wood is needed, which hardware to use, and what type of threshold fits best. Hive CPQ can take that data directly and use it as input for the configuration. That link still needs to be built on our side, but the functionality already exists. So when a factory finishes its digital frame design, we can retrieve that data instantly and generate the perfect matching threshold in our configurator with just one click.”

We now have an incredibly simple way to order digitally. You instantly see what your threshold will look like – and errors are far less likely.

Results

Fewer errors and a clear visual of each configuration

“We now have an incredibly simple way to place digital orders,” says Patrick. “The risk of errors is much smaller, and you immediately see what the threshold looks like – which makes it easier to spot any mistakes early on. Our internal sales team is also very positive: in the past, they had to fill in everything manually, and it was quite complex with lots of exceptions. If we had continued selling this new product the old way, we would’ve needed to hire someone full-time just to keep up.”

If we had continued selling this new product the old way, we would’ve needed to hire someone full-time just to keep up.

Access for dealers only

“Our dealers and their customers are enthusiastic too. They not only see the added value of the new ordering process, but also the potential to connect with other software systems in the future. Anyone who wants to order thresholds gets a personal login for the configurator. We always include a short training session, since orders placed through the configurator go straight into production. That way, we prevent mistakes and ensure everyone can use the system smoothly.”

Process

“Questions were answered the same day.”

“We experienced the collaboration with Hive as very positive,” Patrick continues. “Everything went smoothly, with clear communication and regular follow-ups. You can tell the team knows their stuff – some even have experience with construction-related products, which made working together a lot easier. Whenever we had a question, it was handled the same day. The whole process went very efficiently – everything was up and running within nine months. The ERP integration was the trickiest part, but that was mainly due to the limited accessibility of our own production software. In the end, that turned out fine too.”

You can tell the Hive team knows their stuff – some even have experience with construction-related products.

Future

Expanding the dealer network

Looking ahead, Patrick says: “There are still a few small adjustments to come, but the great thing about Hive CPQ is that we can handle most of those ourselves. Everything runs as it should, but we’ll likely uncover new opportunities for improvement along the way. For now, our focus lies on strengthening our position in the market and expanding our dealer network, so our partners can bring this new solution to their own customers.”