- Home

- Customer cases

- Zolare speeds up order process with Hive Configure Price Quote software

Zolare speeds up order process with Hive Configure Price Quote software

In 2023, sun protection specialist Zolare went all-in on innovation, with a fresh brand identity and a new sales process. The company chose Hive CPQ to simplify quoting for its dealers. We spoke to Frank ter Steege, Commercial & Marketing Manager, who’s been leading the digital transformation of Zolare’s sales process for the past two years.

Introduction

About Zolare

Zolare is a Dutch manufacturer of outdoor sun protection systems, specializing in screens, roller shutters, drop-arm awnings, external venetian blinds, and skylight solutions. Founded in 1977 under the name Pirisol, the company now serves over 250 dealers and delivers more than 10,000 finished products every year. “Our main customers are interior decorators and sun protection specialists,” says Frank. “But we also supply to dormer and window frame installers.”

Problem

A fresh identity and a new order process

“Zolare has seen steady growth since day one, even without much focus on marketing,” Frank explains. “That approach worked: some of our very first customers are still with us today, which says a lot about our service and product quality. But the digital world is changing fast, and I believe in progress. So in 2023, we gave the company a fresh new look: a new name, a renewed focus on product experience, and a website that fits today’s standards. Alongside that, it was time to modernize our ordering process too.”

Zolare has seen steady growth even without much focus on marketing, but the digital world is changing fast, so it was time to modernize our ordering process.

Moving away from incomplete order forms

For many years, Zolare relied on a fairly traditional ordering process. “We worked with printed catalogs, both in-house and at our dealers,” Frank explains. “Orders came in via paper forms, sent by email or even fax. Later on, we moved to a basic order page built in WordPress, but every order still had to be entered manually into our ERP system.”

That approach wasn’t always error-proof. “Sometimes essential details were missing – like the preferred operating side of a shutter – or the configuration wasn’t technically feasible, for example with configurations that had a motor that didn’t match the width of the roller shutter.”

Looking for more ease of use for both team and dealers

“We really wanted to rethink the entire ordering process,” says Frank. “Our goal was to build a user-friendly system, even for dealers who don’t place sunshade orders every day. We wanted to take work off their hands and make it as easy as possible for them to place an order by themselves.

At the same time, we wanted every order to automatically generate the right production parts in our ERP system. Manually entering orders wasn’t just time-consuming, it also increased the risk of mistakes. That’s the step we’re now automating with Hive CPQ.”

Manually entering orders wasn’t just time-consuming, it also increased the risk of mistakes.

Solution

Hive CPQ to the rescue, on both ends

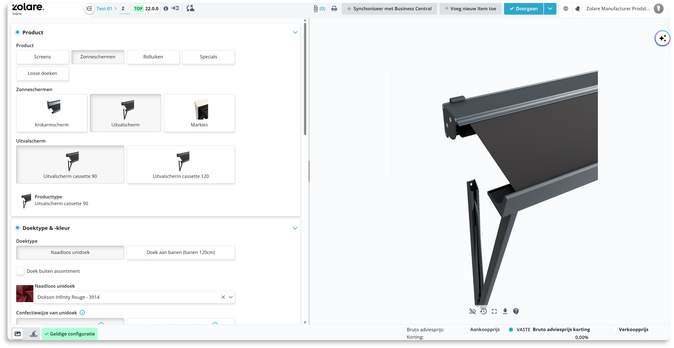

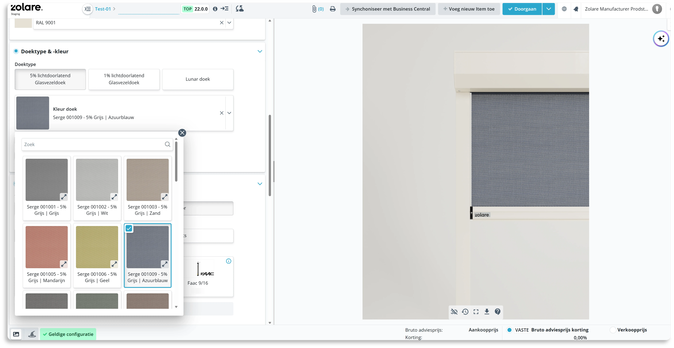

“Today, we use Hive CPQ in two ways,” Frank explains. “On the back end, we now receive complete orders with accurate configurations and pricing. But the biggest change is on the front end, where our dealers can easily create quotes and prices – even together with their customer during a sales conversation – in a transparent way.

The ease of use is really noticeable: Hive CPQ is a perfect fit for our network of interior decorators, who can now use the tool without needing in-depth technical knowledge of our products. Everyone who tested the tool is actively using it and placing orders through Hive. Some dealers even installed a Hive CPQ kiosk in their showroom: it helps them avoid missing options like fabric types or motor variants, and gives their customers a more complete experience.”

The ease of use is a perfect fit for our dealers: they can use the tool without needing in-depth technical knowledge.

90% of dealers already on board

“Our dealers were quick to get on board with the new system. Today, 90% of them actively use Hive CPQ and that adoption happened pretty fast. Month after month, more customers are placing their orders through the platform. It’s hard to pinpoint whether that growth is due to the summer season, our marketing efforts, or the introduction of Hive CPQ, but one thing’s for sure: the new ordering system has become a strong selling point during trade fairs and sales meetings. It’s definitely contributed to the rise in new dealers over the past months.

Another big win is that we can now easily follow up when something goes wrong during ordering. The entire process is more structured and controlled, which clearly strengthens customer relationships. Internally too, everyone’s happy with the move to a modern, intelligent ordering system. We even use Hive CPQ ourselves to generate fast and accurate custom quotes.”

Our new ordering system is a strong sales argument for dealers, and we’ve seen their numbers go up since launching Hive CPQ.

Process

“Hive CPQ’s involvement stood out from the start”

“I researched several CPQ solutions and came across Hive CPQ,” Frank explains. “After an initial call with Vera, their Sales Manager, things moved quickly. What immediately stood out to me was Hive’s personal involvement. When exploring a CPQ tool, it’s often hard to know what to expect or what to look out for during a demo. That’s why proper guidance makes all the difference – and with Hive, I felt that support from day one.”

When exploring a CPQ tool, you don’t always know what to expect – which makes good guidance all the more important. That’s exactly what Hive offered from the very beginning.

From a challenging start to smooth sailing

“We kicked off the project in January 2024,” Frank explains. “Initially, we were working with an English-speaking configurator wizard, but our team operates fully in Dutch. So we quickly switched to a Dutch-speaking consultant – and that’s when things really started moving. The new wizard truly understands our products. Just recently, I forgot to include some information in a briefing, and the Hive consultant spotted it immediately. That kind of proactive thinking is a real added value. Since then, everything’s been running smoothly.”

Zolare chose a phased approach. “We started with our biggest product group – the screens – and only added other categories later on. The moment the screens went live, we launched the system to our dealers. That gave them time to get familiar with the platform, and allowed us to catch any errors along the way. We were transparent about that, and received valuable feedback. We fixed small bugs and gradually improved the configurator, step by step.”

Getting dealers on board turned out to be easier than expected. “New customers receive a one-hour personal training and a few clear manuals. That works well: you just need to guide them briefly, and then they’re off. The system is intuitive enough for them to find their way quickly. All in all, the project was completed in a relatively short time. I made a point of blocking out a few hours each week in 2024 to work on the configurator, and that definitely helped speed things up.”

Future

Next steps: better visualization and ERP integration

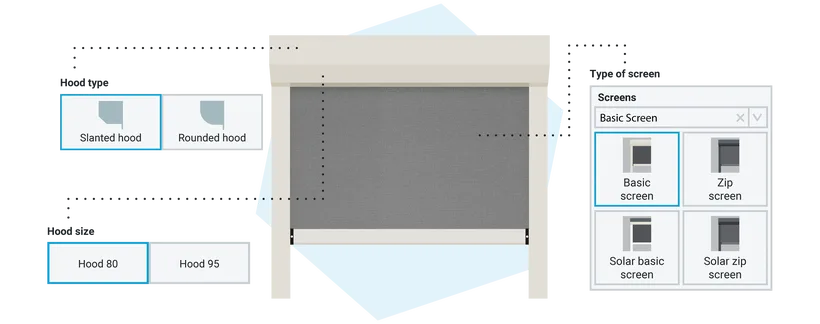

Zolare is currently working on improving product visualization within the configurator. “In the first project phase, users would immediately see an image or render during configuration, but those visuals weren’t always accurate. For example, the fabric color or frame finish didn’t match the selected options. We’ve since aligned those better. We still work with static images: while Hive CPQ fully supports 3D models, that’s less relevant for our products.”

The next big step is integrating Zolare’s Bill of Materials into Hive CPQ and connecting it to their ERP system. “At the moment, orders still have to be entered manually into our ERP. That process is later double-checked by colleagues, which is time-consuming and increases the risk of errors, especially during the busy summer season.

I had underestimated the complexity, and we’re a relatively small team with limited in-house IT knowledge, but we’re doing what we can. It’s important to set this up correctly from the start: if you don’t, you’re building on a shaky foundation. Our goal is to have the BOM and ERP integration fully up and running by the end of this year.”

Product Store and API integrations on the horizon

“Our first goal was to get buy-in from our dealers – and we’ve definitely succeeded. Of course, it would be great if 100% of them eventually placed orders via Hive CPQ, but we’re letting that happen organically. In the meantime, we continue to improve the platform. We’re exploring the idea of setting up a Product Store within Hive for spare parts, and potentially adding features related to complaint handling. Hive CPQ certainly offers the possibilities, but it’s important that our internal processes can keep up. We’re a production company, and we want to keep our lead times stable. So yes, we want to grow, but only in a way that’s sustainable and manageable.

Once our internal systems are fully integrated, we want to explore whether we can connect our customers’ systems to Hive CPQ via API integrations. That would be another step forward in terms of ease and efficiency.”