- Home

- Customer cases

- ETAP chooses Hive CPQ to enable advanced product configuration

ETAP chooses Hive CPQ to enable advanced product configuration

ETAP Lighting, a Belgian manufacturer of sustainable and ergonomic lighting solutions, is fully committed to digitalization and automation. With over 70 years of experience and a strong European network, ETAP distinguishes itself through its advanced focus on energy efficiency, innovation, and customization. Thanks to Hive CPQ, the company can now respond more quickly, efficiently, and scalably to customer-specific requirements.

Introduction

ETAP: Smart, circular, and Belgian

ETAP Lighting International is a leading Belgian manufacturer of high-quality lighting solutions for professional environments such as hospitals, offices, schools, and industrial sites. The focus on customization and sustainability makes ETAP unique. Customers who choose ETAP benefit from a comprehensive, worry-free solution: from intelligent lighting control systems to minimal maintenance requirements and seamless integration of emergency lighting.

In terms of sustainability, ETAP is a trendsetter in circular lighting solutions. The company is committed to initiatives such as refurbishment programs for old fixtures and Circular Light as a Service: a circular model where lighting solutions are returned, reused, or recycled after use. Thanks to smart technologies, extended product lifespans, and higher retention rates, customers can reduce their CO2 emissions by up to 80%. ETAP thus combines minimal impact on natural resources with maximum visual performance for a safe, comfortable, and future-oriented working environment.

With 7% of the annual turnover invested in R&D, its own laboratories and flexible European production, ETAP is not only a local player but also a technological pioneer. Their ideal customer? An organization that values quality, sustainability and tailored solutions, and that partners with an expert who manages everything from design to circular take-back.

Problem

From MTO to scalable configuration

In order to serve their customers faster and more efficiently, ETAP has launched an extensive digital transformation in recent years. This also included a review of the sales process. ETAP offers an extensive range of lighting solutions, from standard products to fully customized solutions. This flexibility is an asset, but it also presented challenges.

A significant proportion of the orders were Made To Order (MTO), which meant that the engineering department had to manually verify each configuration before quoting. This led to delays for customers and a high workload for engineers.

ETAP wanted to address this by converting as many MTO products as possible to Configure To Order (CTO). This allows the sales department to configure products independently and prepare quotes immediately, without the intervention of engineering. This not only increases speed, but also makes the sales process more scalable. At the same time, the manufacturer wanted to avoid this leading to additional administration for production. It was therefore crucial that the software solution could automatically generate a Bill of Materials (BOM), routing, and Bill of Labor (BOL) for each order.

Solution

The solution: a user-friendly and integrated CPQ platform

ETAP presented its challenge to digitalization partner Cegeka, and Hive CPQ quickly emerged as the right solution. With this platform, sales representatives would be able to configure products and generate quotes themselves, without needing engineering. This means shorter lead times, less workload for R&D, and faster response times for customers.

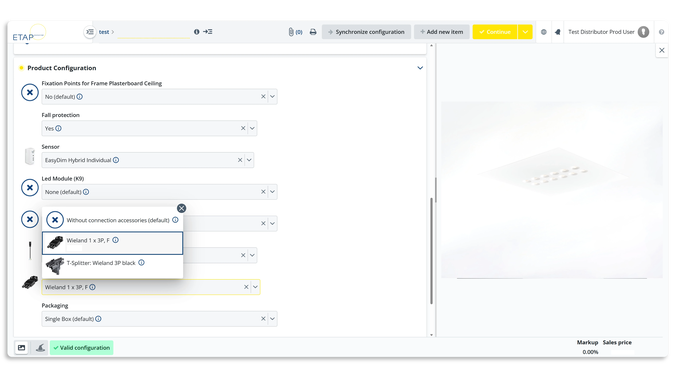

Hive CPQ proved to be tailored to ETAP’s needs. The software makes it easy to manage configurable products and is user-friendly enough so that even non-IT professionals know how to use it. The configurations automatically generate a visually appealing quotation, including accurate price calculations and delivery time estimates. Hive CPQ is also multilingual, a must for an internationally active player like ETAP.

It was important that the implementation was not just about the CPQ solution but also about aligning the master data in both ERP and CPQ. To this end, Hive CPQ was connected to Microsoft Dynamics 365 Finance & Supply Chain Management. Thanks to this integration:

- Hive CPQ automatically generates product codes based on the selected options and forwards them to FSCM

- Bill of Materials (BOM) and routing data are forwarded directly to the ERP

- And Hive CPQ takes into account the product lifecycle status of product variants in FSCM.

This integration drastically reduces the risk of errors and ensures that the production process is controlled correctly from the outset. ETAP customers benefit from the same flexibility as before but now get faster, fully accurate quotes – with the right configuration, a suitable price, and a correct delivery time. This translates into higher conversion rates and greater trust in the brand.

Process

Phased implementation with maximum coordination

ETAP deliberately opted for a phased implementation, with a focus on coordination, training, and ease of use. Together with Cegeka, they laid a solid foundation first by drastically reducing the number of MTO products. At the same time, product coding, structures, and pricing models were critically reviewed and optimized.

In the first phase, relatively simple product models were set up in Hive CPQ. Once those configurations were working well, integration with Microsoft Dynamics 365 Finance & Supply Chain Management followed. Thanks to the Hive connector, the platform was able to seamlessly exchange Bill of Materials, routing information, and pricing data with the ERP system – an important step toward a fully automated process.

After these technical integrations, Hive CPQ was first rolled out internally. Sales representatives could now configure products and generate quotes themselves. The platform is now also available to external users: customers can now put together their desired lighting solution and request a quote immediately. By taking a phased approach to implementation and investing in good training, ETAP’s sales teams were able to quickly embrace the new way of working.

Future

Scalable product configuration and more automation

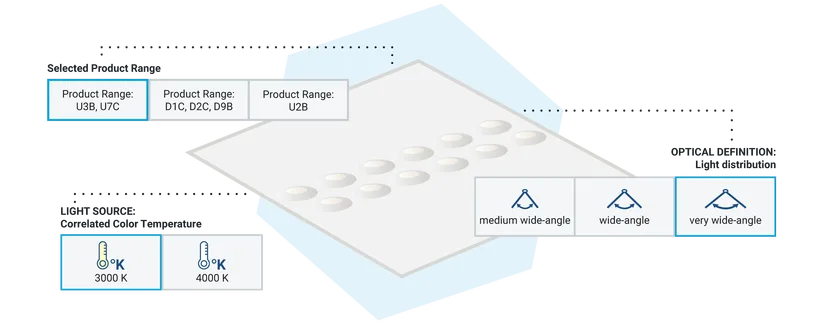

ETAP will continue to focus on flexibility, automation, and scalability in the future. The number of MTO products will be further reduced in favor of configurable functionalities such as driver type, color temperature, or light output. Hive CPQ will remain the central platform for managing this variability.

ETAP is currently working on integrating a new product family into the platform: emergency lighting. This will broaden the configuration possibilities without sacrificing usability or speed.

In addition, integrations with other systems are also being further developed. In collaboration with Cegeka, ETAP is investigating new links between Hive CPQ, their website, and the PIM system Pimcore. The goal is clear: Responding even more quickly to specific customer requirements while maintaining flexibility and quality.